Contents

Sofia Klein

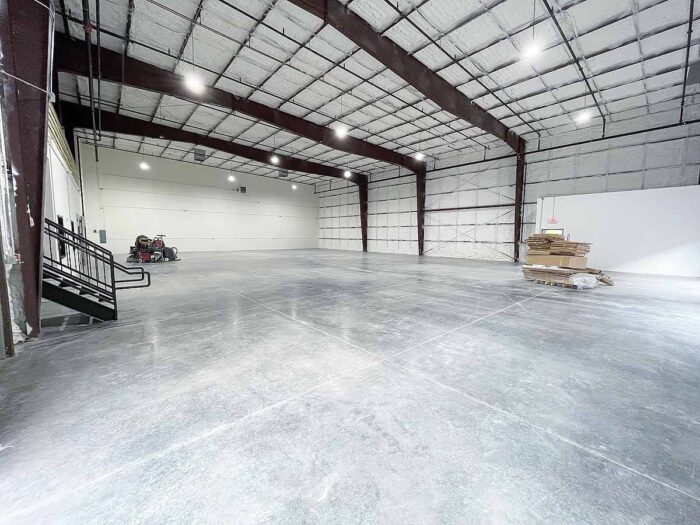

Walk into any modern building today and you’ll likely see polished concrete floors. This isn’t just a trend—it’s become the go-to choice for architects, designers, and building owners who want something that looks great and actually works for decades. While other materials come and go, polished concrete floors have proven themselves in everything from cozy homes to massive warehouses.

The shift toward polished concrete happened for good reasons. Architects got tired of specifying materials that looked nice for a few years, then needed constant repairs or complete replacement. They wanted something that could handle real-world use while still looking professional. That’s exactly what polished concrete delivers, and it’s why this material has moved from industrial spaces into high-end residential and commercial projects.

You’ll find polished concrete in tech offices, retail stores, restaurants, and modern homes. It works because it solves multiple problems at once. Where you might have needed separate solutions for durability, aesthetics, and maintenance, polished concrete handles all three. This practical approach mirrors how sustainable construction practices have become standard—not because they’re trendy, but because they make sense.

The popularity surge also comes from how versatile polished concrete can be. You can make it look industrial and raw, or refined and elegant. You can score patterns into it, expose different aggregates, or keep it smooth and simple. This flexibility means architects can use one material system throughout a project while creating different looks for different spaces.

What Are the Pros and Cons of Polished Concrete Floors?

Let’s be honest about what polished concrete can and can’t do. Like any material, it has strengths and weaknesses. Understanding both sides helps you make the right choice for your project.

The Major Advantages

Polished concrete floors last incredibly long. We’re talking 20-30 years of heavy use with minimal maintenance. The surface actually gets denser and more durable over time, which is the opposite of what happens with most flooring materials. You won’t see the gradual wear patterns that make other floors look tired after a few years.

The cost savings add up fast. Yes, you’ll pay more upfront compared to basic options like vinyl or carpet. But you’ll never replace it. No ripping out old flooring, no disposal costs, no downtime while new material gets installed. The math works out in your favor, especially in commercial spaces where flooring replacement means shutting down business.

Maintenance is ridiculously simple. Regular mopping with pH-neutral cleaner is basically all you need. No waxing, no sealing, no special products. Spills stay on the surface where you can wipe them up immediately. The dense surface doesn’t harbor bacteria or absorb odors, which matters a lot in restaurants, healthcare facilities, and homes with pets.

The aesthetic flexibility surprises people. You can create everything from sleek, modern looks to rustic, industrial vibes. Different aggregate exposure levels give you texture options. Scoring patterns add visual interest. You can even integrate with terrazzo tiles for transition areas or decorative accents.

The Real Limitations

Installation quality matters more than with other flooring types. A bad polished concrete job can’t be easily fixed—you’re looking at starting over. This means you need contractors who really know what they’re doing, and they’re not available everywhere. In some markets, finding skilled installers can be challenging and expensive.

The material feels hard and cold. If you’re barefoot a lot, like in residential bedrooms, this might bother you. The thermal mass characteristics that make polished concrete great for passive solar heating can work against you in poorly insulated spaces. You’ll feel the cold coming up through the floor in winter.

Sound bounces around more than with carpet or other soft materials. This can create echo problems in large spaces or rooms with high ceilings. You’ll need to plan for acoustic treatments like wall panels, ceiling treatments, or area rugs to manage noise levels. The issue becomes more noticeable in spaces where people are talking or music is playing.

Cracking can happen, especially if the substrate wasn’t properly prepared or if the building settles. While small cracks can add character, larger ones might need repair. The monolithic nature that makes polished concrete so durable also means you can’t just replace a section like you could with tile or planks.

You need to think about insulation materials and systems more carefully. The thermal bridging properties of concrete can create comfort issues without proper building envelope design.

How Much Does Polished Concrete Flooring Cost?

The money conversation around polished concrete gets complicated because people often compare apples to oranges. You can’t just look at initial installation costs—you need to think about what you’ll spend over the life of the building.

Initial Installation Costs

Basic polished concrete runs $8 to $15 per square foot for straightforward installations. This covers grinding, polishing, and basic densification. If you want decorative aggregates, custom scoring patterns, or colored concrete, expect $20 to $25 per square foot. High-end installations with complex designs or special finishes can go higher.

These numbers put polished concrete in the middle range for quality flooring. You’ll pay more than basic carpet or vinyl, but less than natural stone or premium hardwood systems. The key difference is that polished concrete is a one-time expense, while other materials need periodic replacement.

Location affects pricing significantly. Urban areas with experienced contractors tend to be more expensive but offer better quality control. Rural areas might have lower labor costs but fewer skilled installers. The size of your project matters too—larger areas benefit from economies of scale.

Long-Term Value Analysis

Here’s where polished concrete really shines. Traditional flooring materials follow predictable replacement cycles. Carpet lasts 7-10 years. Vinyl flooring needs replacement every 10-15 years. Even ceramic tile grout requires renewal every 15-20 years. Each replacement means material costs, labor costs, and business disruption.

Polished concrete breaks this cycle. A properly installed floor can last 30-50 years with only routine cleaning and occasional repolishing. When repolishing becomes necessary (usually every 10-15 years), it costs a fraction of full replacement and can be done in sections during off-hours.

The maintenance cost difference is substantial. Other flooring materials need special cleaners, periodic treatments, or component replacements. Polished concrete needs water and basic cleaner. No stripping and waxing. No grout cleaning. No board replacement. The simplicity translates to real savings over time.

Energy costs can be lower too. The thermal mass helps regulate temperature swings, reducing heating and cooling loads. The light-colored surface reflects more light, potentially reducing artificial lighting needs. These benefits aren’t huge, but they add up over decades.

Project-Specific Factors

Existing substrate conditions affect costs significantly. If you’re working with a new concrete slab, installation is straightforward. Older concrete might need repairs, patching, or additional surface preparation. Severely damaged concrete could require overlay systems that increase costs.

The complexity of your space matters. Simple rectangular rooms are cheaper to polish than areas with lots of columns, stairs, or built-in fixtures. Each obstacle requires hand work that increases labor time. Consider these factors when comparing quotes from different contractors.

Projects that incorporate concrete recycling strategies can reduce material costs while supporting environmental goals. Using recycled aggregates or incorporating reclaimed materials can create unique looks while reducing overall project costs.

Is Polished Concrete Better Than Tile?

The polished concrete versus tile debate comes up constantly in design meetings. Both materials have their place, but they serve different needs. Understanding when to use each one will save you headaches later.

Maintenance and Durability Comparison

Tile systems have a fatal flaw—grout lines. These joints collect dirt, stain easily, and eventually fail. Even the best grout requires periodic cleaning, sealing, and replacement. In commercial kitchens, healthcare facilities, or high-traffic areas, grout maintenance becomes a constant expense.

Polished concrete eliminates this problem entirely. The monolithic surface has no joints to maintain. Spills can’t penetrate between tiles because there are no tiles. Cleaning is uniform across the entire surface. This advantage becomes more valuable in larger spaces where grout line maintenance would be extensive.

Impact resistance strongly favors polished concrete. Dropped tools, heavy equipment, or furniture impacts that would crack tiles barely mark polished concrete. The dense surface actually gets stronger with normal wear, while tiles can chip or crack from single impact events.

Design Flexibility and Aesthetics

Polished concrete excels at creating seamless transitions. You can run the same material from interior to exterior, up walls, or into integrated elements like concrete staircase concepts. This continuity creates clean, modern looks that work well in contemporary design.

Tile offers more decorative options. You can create intricate patterns, use multiple colors, or incorporate decorative elements that aren’t possible with polished concrete. If your design needs specific colors or complex patterns, tile might be the better choice.

The scale of your project affects this comparison. Small residential bathrooms might benefit from tile’s decorative flexibility. Large commercial spaces usually benefit from polished concrete’s maintenance advantages and visual continuity.

Performance in Specific Applications

Wet areas traditionally favor tile because of slip resistance and waterproofing. Modern polished concrete can be textured for slip resistance, but tile still has advantages in shower areas or swimming pool decks. The grout lines that cause maintenance headaches in dry areas actually provide traction in wet conditions.

Temperature considerations matter too. Tile provides better thermal insulation than polished concrete. In areas where floor temperature matters—like bedrooms or areas where people sit on the floor—tile might be more comfortable.

Chemical resistance varies by application. Polished concrete handles most common chemicals well, but specialized environments might need the chemical resistance of specific tile types. Laboratory or industrial settings might require tile systems designed for chemical exposure.

How Long Do Polished Concrete Floors Last?

The lifespan question depends on what you mean by “last.” Are you talking about structural integrity, visual appearance, or functional performance? Polished concrete performs differently than traditional flooring materials in each category.

Structural Lifespan

Well-executed polished concrete floors can last 30-50 years structurally. Some installations from the 1990s still perform like new despite decades of heavy commercial use. The polishing process creates a surface that’s actually denser than the original concrete, so it keeps getting stronger over time.

The key phrase is “well-executed.” Poor installation, inadequate substrate preparation, or wrong concrete mix design can cut lifespan significantly. This is why contractor selection matters so much with polished concrete—you’re making a long-term investment that’s hard to fix if it goes wrong.

Environmental factors affect longevity. Indoor controlled environments provide ideal conditions for maximum lifespan. Outdoor exposure, freeze-thaw cycles, or chemical contamination can reduce performance periods. Even in challenging conditions, polished concrete typically outlasts alternative materials.

Visual and Functional Performance

The appearance of polished concrete actually improves with age in many cases. The surface develops a patina that adds character rather than looking worn. This is completely different from carpet, vinyl, or even hardwood that show linear degradation from day one.

Functional performance stays consistent for decades. You won’t see the gradual decline in performance that happens with other materials. Traffic patterns don’t create worn paths. The surface doesn’t become uneven or develop soft spots.

When renewal becomes necessary, it’s usually repolishing rather than replacement. This process can restore the surface to like-new condition while preserving the original substrate investment. The cost and disruption are minimal compared to complete flooring replacement.

Factors That Extend Lifespan

Proper initial installation is crucial. This includes adequate concrete thickness, proper mix design, correct curing procedures, and skilled polishing work. Cutting corners on any of these factors will reduce lifespan significantly.

Regular maintenance extends performance. While polished concrete is low-maintenance, it’s not no-maintenance. Regular cleaning and prompt attention to any issues will maximize lifespan. The good news is that maintenance requirements are minimal compared to other flooring types.

Climate control helps. Consistent temperature and humidity reduce thermal stress cycles that can cause cracking. This is especially important in regions with extreme seasonal temperature swings.

Integration with pigmented concrete systems can provide color that lasts the full lifespan of the floor. This eliminates the fading and color wear that plague many traditional flooring options.

What Is the Difference Between Polished and Sealed Concrete?

People often confuse polished concrete with sealed concrete, but they’re completely different approaches to concrete finishing. Understanding the difference helps you choose the right option for your project.

Polished Concrete Process

Polished concrete is mechanical densification. Contractors use progressively finer diamond abrasives to grind and polish the surface. This process densifies the concrete itself, creating a wearing surface that’s integral to the substrate. There are no coatings or separate layers—the polished surface is the concrete.

The process reveals the natural character of the concrete. Aggregate patterns, color variations, and subtle textures become visible as the surface is refined. This creates authentic material expression that connects with trends toward honest material use in contemporary design.

Different levels of polishing create different looks. Light polishing reveals some aggregate and creates a matte finish. Heavy polishing exposes more aggregate and creates a glossier surface. You can stop at any point to achieve the look you want.

Sealed Concrete Systems

Sealed concrete relies on topical coatings applied over the concrete surface. These might be epoxy, polyurethane, or acrylic systems. The coating provides protection and aesthetic enhancement, but it’s a separate layer that sits on top of the concrete.

Sealed systems can provide bright colors, high-gloss finishes, or decorative effects that aren’t possible with polished concrete. They can also be installed more quickly and with less specialized equipment. For projects where installation speed matters, sealed systems might be preferable.

The trade-off is durability and maintenance. Coatings can delaminate, wear unevenly, or require periodic renewal. They’re also more prone to damage from impacts or chemical exposure. When coatings fail, you might need to strip and reapply the entire system.

Performance Differences

Polished concrete performs as a single integrated system. There are no layers to separate or wear differently. The surface degrades gradually and predictably, allowing for planned maintenance rather than emergency repairs.

Sealed systems create potential failure points wherever the coating meets the substrate. Temperature changes, moisture infiltration, or substrate movement can cause coating failure. When this happens, the entire system performance is compromised.

Maintenance requirements differ significantly. Polished concrete needs only basic cleaning and occasional repolishing. Sealed systems might need coating renewal every 5-10 years, depending on traffic and environmental conditions.

The aesthetic differences are substantial. Sealed systems can look artificial or synthetic, especially in high-end architectural applications. Polished concrete reveals the inherent beauty of the material itself, creating authentic textures and patterns that work well in sophisticated designs.

How Do You Maintain Polished Concrete Floors?

One of the biggest advantages of polished concrete is how easy it is to maintain. This isn’t marketing fluff—the maintenance requirements really are minimal compared to other flooring materials.

Daily and Weekly Maintenance

Regular cleaning couldn’t be simpler. Sweep or dust mop to remove loose dirt and debris. Then mop with pH-neutral cleaner and water. That’s it. No special products, no complicated procedures, no waiting for surfaces to dry or cure.

The non-porous surface means spills stay on top where you can clean them immediately. Coffee, wine, oil, or other substances that would stain porous materials wipe up easily from polished concrete. This immediate cleanup prevents staining and eliminates the need for special stain removal products.

Avoid acidic cleaners like vinegar or citrus-based products. These can etch the surface over time. Also avoid ammonia-based cleaners that can create a film. Stick with pH-neutral cleaners designed for concrete surfaces, or even just water for light cleaning.

Long-Term Maintenance

Professional repolishing every 10-15 years maintains the surface quality. This process removes minor scratches, restores gloss levels, and extends the floor’s lifespan. The timing depends on traffic levels and use patterns—high-traffic commercial spaces might need repolishing more frequently than residential areas.

Repolishing is much less disruptive than replacing other flooring materials. The work can often be done in sections during off-hours or low-traffic periods. There’s no demolition, no disposal of old materials, and no extended downtime while new materials are installed.

The cost of repolishing is typically much lower than replacing other flooring materials. You’re maintaining the existing surface rather than starting over. This economic advantage becomes more significant over time as other materials require multiple replacement cycles.

Preventive Care

Use walk-off mats at entrances to reduce tracked-in dirt and moisture. While polished concrete is durable, preventing dirt and grit from entering the space reduces micro-scratching and keeps the surface looking its best.

Furniture pads prevent scratches from moving chairs, tables, or equipment. While polished concrete is harder than most flooring materials, metal furniture legs or equipment can still mark the surface if dragged across it.

Address any cracks or damage promptly. Small cracks can be repaired relatively easily, but larger damage might require more extensive work. Regular inspection helps catch issues before they become major problems.

The simplicity of polished concrete maintenance aligns perfectly with modern facility management practices. Like how concrete pipes inspired architects to create functional yet beautiful elements, polished concrete represents practical design that works in the real world.

The widespread adoption of polished concrete reflects a shift toward smarter material choices in architecture and design. Instead of choosing materials based solely on appearance or initial cost, more people are considering long-term performance, maintenance requirements, and environmental impact. Polished concrete succeeds because it excels in all these areas while still providing the aesthetic flexibility that architects and designers need.

This practical approach to material selection suggests that polished concrete isn’t just a trend—it’s become a standard option for projects where durability, maintainability, and cost-effectiveness matter. As building owners and designers continue to prioritize long-term value over short-term savings, polished concrete’s advantages become even more compelling.

Tags: architectural concretearchitectural flooringBuilding Materialsconcrete finishesconcrete surface finishesconcrete vs tile flooringconstruction costsdurable flooring materialsfloor maintenanceGreen BuildingPolished Concretepolished concrete costPolished Concrete Floorspolished concrete maintenanceSustainable Designsustainable flooring options

Sofia Klein

Sofia Klein is a Projects Editor at Arch2O, originally from Germany, with a Master’s in Architecture and Urban Design from the Technical University of Munich. Since joining Arch2O in October 2023, she has helped shape the platform’s editorial direction, focusing on sustainability, cultural relevance, and urban innovation. With nearly a decade of experience in architecture and editorial work, Sofia brings clarity and depth to every project she curates. Her ability to transform complex ideas into accessible narratives bridges the gap between professionals and the public, strengthening Arch2O’s role in global architectural discourse.